Catalogues

- NFC Tags

- Paper NFC tagsOn Metal NFC tagsTamper proof nfc tagsFPC NFC tagsSpecial NFC tags

- NFC Cards

- Plastic NFC cardsPaper NFC cardsLF RFID cardCPU / JAVA card

- NFC Key fobs

- Epoxy NFC key tagsPlastic NFC key fobs

- NFC Reader writer

- Fixed NFC reader writerHandheld RFID readerUSB token NFC readerLF RFID Reader

- NFC Wristband

- Reusable NFC wristbandsOne-off NFC wristbands

- RFID inlay

- Sheet type RFID inlayRoll type RFID inlay

- RFID Tag

- RFID Laundry TagRFID Asset TagRFID Pallet Tag

- Smart Device

- RFID Smart CabinetRFID Library DeviceRFID TunnelRFID Retail Device

- RFID Security Gate

- RFID gate

- Library RFID Tags

- RFID Book TagRFID Disc Tag

- UHF Tags

- EPC Gen 2 UHF tagJewelry RFID tagTamper Proof UHF tagRFID Windshield TagCable Tie RFID TagRFID garment tagRFID Clothing Hard TagDual frequency RFID tagRFID Medical TagLED UHF TagARC Certified UHF Tag

- UHF Cards

- UHF Smart Card

- UHF Wristband

- RFID Wristbands

- UHF Reader writer

- Fixed UHF ReaderMobile RFID ReaderR2000 UHF readerE Series UHF readerC Series UHF reader

- UHF Antenna

- UHF RFID Antenna

- On metal RFID Tag

- UHF Metal tagCeramic UHF metal tagFlexible UHF Metal TagPCB UHF Metal Tag

- Animal Tag

- RFID ear tagRFID Animal ReaderInjectable RFID tagRFID foot ring tag

- More Recommend

- RFID asset tagRFID screw tagRFID Seal Tag

GEE-UR-BW C Series Desktop UHF RFID Reader

150x 110 x 26mm, 860- 960 Mhz, 0- 30 dbm, impinj R500, 30 cm read distance, USB interface, support Windows, Linux, Andriod OS

Download Specification

GEE-UR-BW C series desktop USB uhf rfid reader specification.pdf

OverviewSpecificationApplicationsSupport

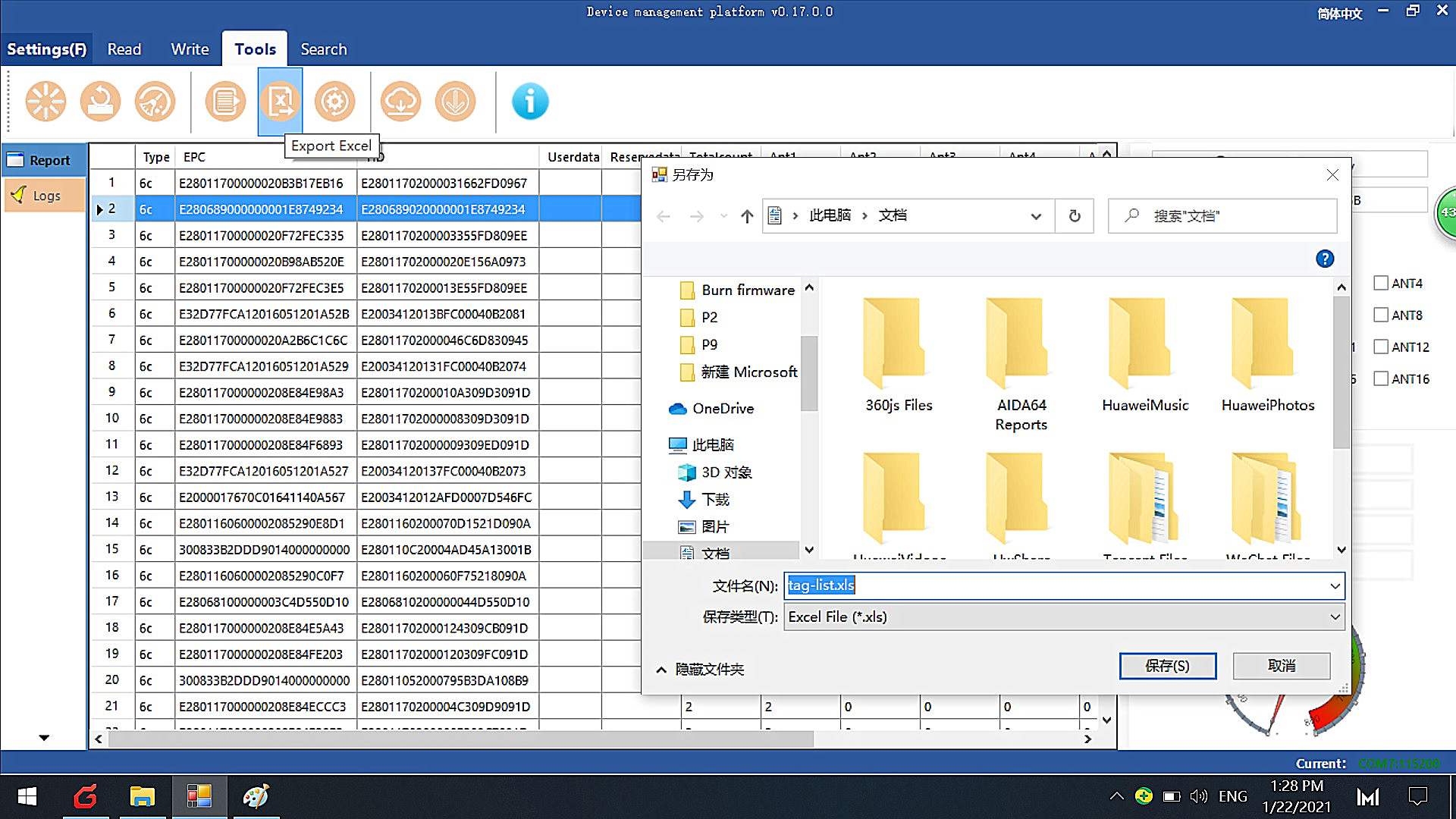

GEE-UR-BW is a C series desktop UHF RFID reader with USB Type-C Interface. Worked at 860- 960 Mhz, it can read rfid tag at distance of 30 cm with high inventory speed, support fast reading and writing, batch export tag information to excel file, which is widely used in tag encoding, access control fields.

Video list

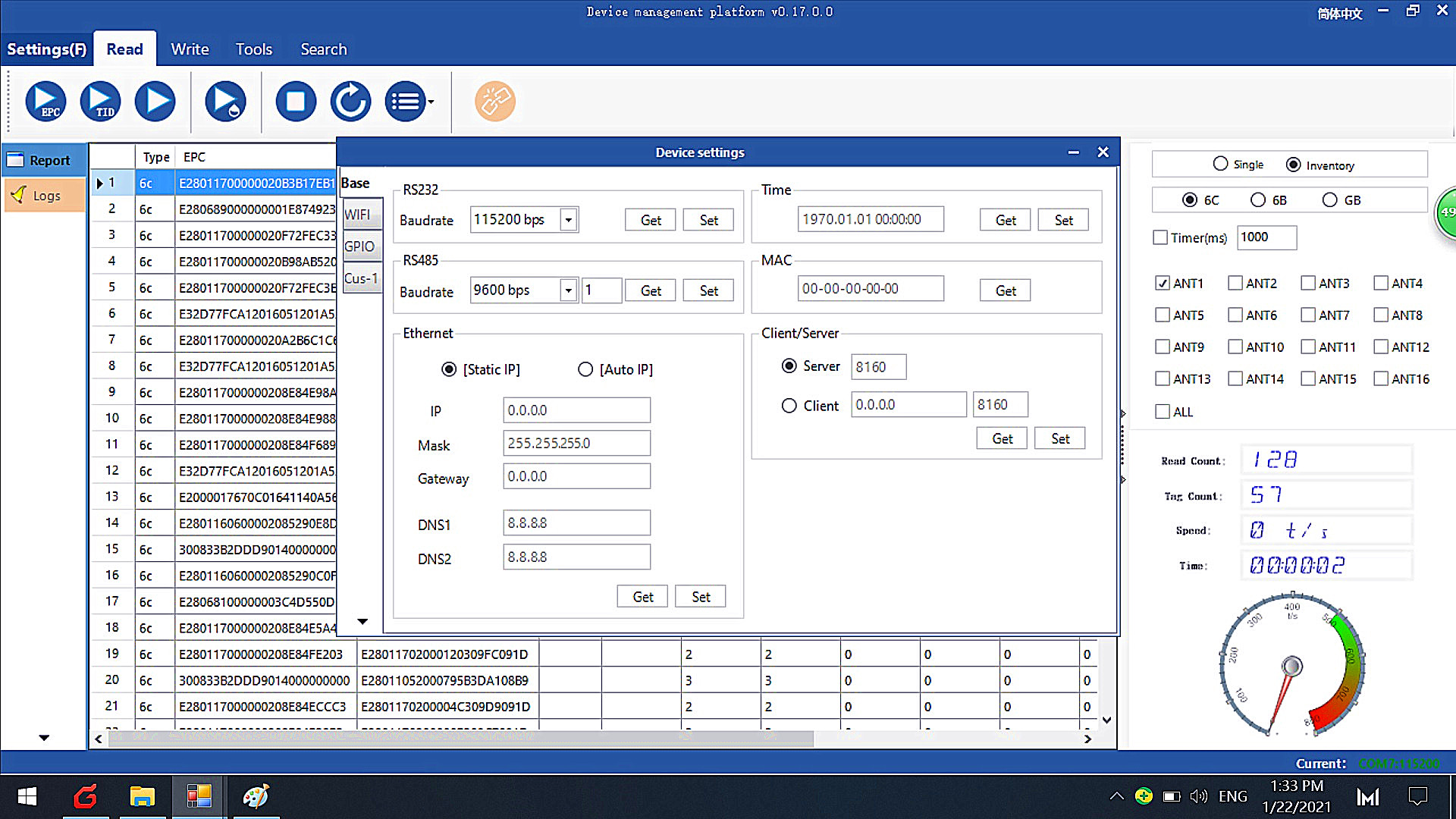

C Series UHF RFID Reader Demo software guidance Part I -setting

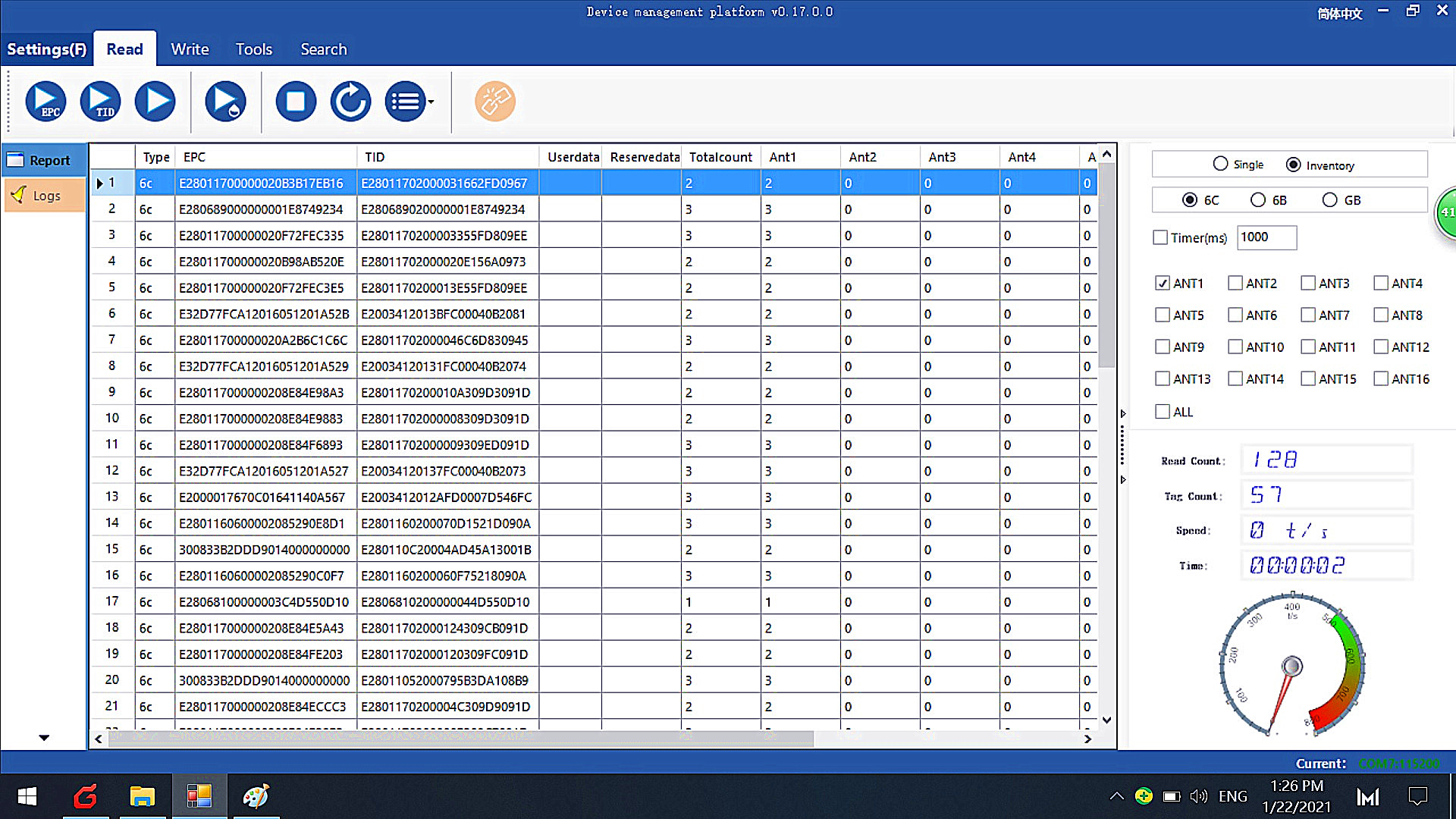

C Series UHF RFID Reader Demo software guidance Part II - Read

C Series UHF RFID Reader Demo software guidance Part III - Write

Software

Main features:

• 160 x 110 x 26 cm, ABS enclosure

• 860-960 Mhz, ISO18000-6C RFID tag supported

• Imping R500 module, 0- 30 dbm output, up to 30 cm read distance

• built-in circular polarized antenna and buzzer

• USB Type-C interface

• Support Windows, Andriod, Linux system, provide X86 & X64, C++, C#, JAVA source code

• ISO9001 Quality control system just for quality

• CE, FCC certificate

| Physical | |

| Material | Acrylic panel, Aluminum frame |

| Size | 150 mm( L) x 110 mm ( W) x 26mm (H) |

| Weight | 0.35 kg |

| Protocol | ISO18000-6C & EPCglobal Class I Gen 2 |

| RF | |

| Frequency | US 902~ 928 Mhz, EU 865~ 868 Mhz |

| UHF Module | Impinj R500 |

| Antenna | Built-In circular polarized antenna |

| RF output | 0- 30 dBm ( software adjustable, +1 dbm/ stp) |

| Read Distance | 30 cm |

| Power supply | DC5V |

| Interface | USB Type-C |

| Software | |

| Software | Demo software, SDK, API |

| Environment | |

| Operating condition | -20 ~ 60 C, 5~ 95% RH, no condensation |

| Storage condition | -5 ~ 45 C, 5~ 95% RH, no condensation |

RFID, or Radio-Frequency Identification, is a method of storing data and retrieving it via radio waves. Much in the same way a barcode can store information about a type of product, RFID tags contain unique identifiers that correspond to inventory database records. Switching to RFID in your logistics chain offers some significant advantages over traditional inventory control methods.

WIRELESS SCANNING

One of the major advantages of RFID in logistics is how quickly RFID tags can provide information compared to barcoding or other systems. With a barcode, you have to pass each code over a scanner to register the item. RFID works wirelessly, so you can point a scanner at a box of items and register each one without having to take them out first. A powerful enough RFID scanner could inventory entire rooms at once, making inventory tracking a much faster process.

UNIQUE TRACKING

RFID tags contain a microchip or other storage device that can contain a large amount of information. This allows you to place individual identifiers on products, rather than using a single barcode for an entire class of items, and to follow individual items through your logistics chain, instead of needing to extrapolate that data from inventory numbers. This also allows you to track a defective item back to its source in a much easier manner than with other tracking methods.

REAL-TIME UPDATES

Because scanning and inventory control is much faster with RFID than with other forms of management, the system lends itself to integration with wireless communication systems and real-time inventory management systems. This allows you to query the database at any time and find out exactly how much of a given product you have on hand, instead of getting numbers that may be days or weeks old. RFID scanners built into the entrances of warehouses can even scan crates as they enter and leave, providing instant updates of inventory totals that can propagate to other users across the company network.

INTEGRATION WITH OTHER SYSTEMS

The same RFID tags that provide inventory information can also provide other services as well. Security scanners at building exits can let your system know instantly when any product leaves the premises, allowing you to spot theft or misdirected shipments quickly and correct the problem. Likewise, scanning RFID tags at entry and exit points allows confirmation of shipping and delivery of goods, allowing you to trace a shipment as it moves through your logistics chain, and provide accurate estimates of arrival to customers or other business units.

Related Products

-

GEE-UR-C9 C Series 9 dbi UHF RFID Reader >

300x 300 x 70mm, 9 dbi antenna, impinj R2000, 0- 33 dbm, up to 10 meter read distance, ISO18000-6C & EPC C1G2 protocol

NFC Tags

NFC Tags NFC Cards

NFC Cards NFC Key fobs

NFC Key fobs NFC Reader writer

NFC Reader writer NFC Wristband

NFC Wristband RFID inlay

RFID inlay RFID Tag

RFID Tag Smart Device

Smart Device RFID Security Gate

RFID Security Gate Library RFID Tags

Library RFID Tags UHF Tags

UHF Tags UHF Cards

UHF Cards UHF Wristband

UHF Wristband UHF Reader writer

UHF Reader writer UHF Antenna

UHF Antenna On metal RFID Tag

On metal RFID Tag Animal Tag

Animal Tag More Recommend

More Recommend Media & Ads

Media & Ads Transportation & Ticketing

Transportation & Ticketing Library & AssetsManagement

Library & AssetsManagement Logistics & Tracking

Logistics & Tracking Access control

Access control Retail & Gas station

Retail & Gas station Texile solution

Texile solution Health & Medicine

Health & Medicine Food & Wine

Food & Wine Apps for NFC mobile

Apps for NFC mobile Apps for Industry & Retail

Apps for Industry & Retail Manuals

Manuals Software

Software FAQ

FAQ Service Center

Service Center How to choose right tags

How to choose right tags Company news

Company news Industry news

Industry news Technical communication

Technical communication